What are trailer side marker lights? What can they do? How can we install them and avoid potential problems in the future? Through this article, I will provide you with a one-stop solution to these puzzles that have troubled you for a long time!

Side marker lights are lamps installed on both sides of a vehicle, generally applied to reinforce the visibility of the vehicle's sides. Their importance is obviously seen at night or in low-visibility conditions. By marking the outline of the trailer, they alert other road users to keep a safe distance.

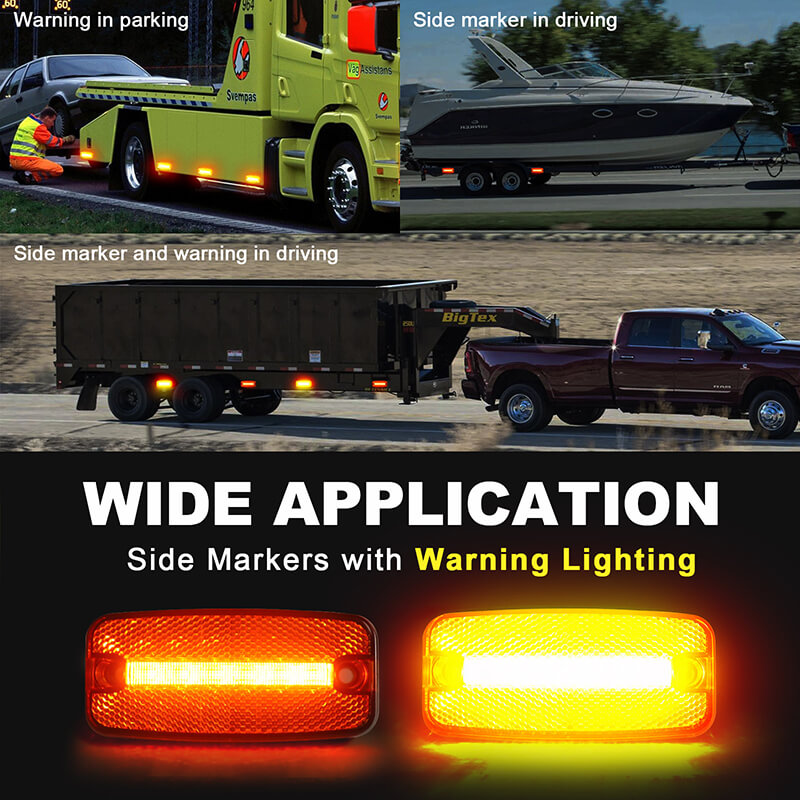

The AgriEyes W226 is a two-piece, two-in-one amber LED trailer side marker light. Each light is equipped with 6 LED beads and its brightness reaches the SAE Class I level. What's more remarkable is that this light allows users to choose to turn on only the side marker light mode or turn on both modes while driving. Simply put, when the vehicle pulls over temporarily, the warning light can enhance visibility and provide better safety protection.

Meanwhile, the built-in reflective reflector design enables the vehicle can still be seen when it is parked with the engine off. Its lamp base is completely made of aluminum, the materials which have excellent heat dissipation performance. And led lighting design dramatically extends the lamp's lifespan to 50,000 hours. Surprisingly, its IP67 waterproof rating enables it suitable for various weather conditions, which is pretty cool!

Select the Appropriate Location: According to the specific situation of the vehicle, reasonably plan the route of the new wires. It is generally suggested to start wiring from the front of the trailer, and then extend along both sides of the vehicle body to the rear.

Preparing Tools and Materials: Ensure that you have prepared the necessary tools and materials, such as screwdrivers, wrenches, electrical tape, waterproof connectors, etc. Carefully read the manufacturer's instructions to understand the specific operation steps and precautions.

Install the Mounting Bracket: It is easy to install the mounting bracket in the selected location, by using tools above-mentioned. Make sure all screws are fully tightened or locked in place to prevent loosening during driving.

Connect the Wires: Each truck side marker light is equipped with 4 connecting wires (black: ground wire, red: warning light wire, yellow: side marker light wire, green: synchronization wire). Connect these wires to the corresponding power lines respectively, ensuring that each connection point is secure and well waterproofed.

Test the Functions: After installation, start the main vehicle and test the functions of all lights. Pay attention to checking the connection of the synchronization wire to ensure that multiple amber side marker lights can flash simultaneously.

Generally, it is recommended to provide an independent ground wire connection for each light when installing side marker lights. The grounding method of traditional single-wire lights through screws is prone to poor contact, especially when used in a saline environment, this design is extremely likely to fail. Therefore, choosing LED lights with two pins and laying a separate ground wire for each light can effectively avoid electrical failures.

Unstable Electrical Connections: Due to the vibrations and bumps that the trailer experiences during driving, wire joints may become loose or break.

Poor Waterproof Performance: The sealing of some trailer lights is not good enough. When the vehicle wades through water or encounters heavy rain, moisture may seep into the interior of the lights, causing short circuits or other electrical failures. This is especially common for connectors and wires that have not been properly waterproofed.

Light Quality Issues: If inferior LED light products are used, the lights are likely to malfunction. The grounding method of traditional single-wire lights through screws is prone to poor contact. It is recommended to use lights with two or more wires.

Regular Inspection and Maintenance: Regularly check all electrical connection points to ensure they are tight and show no signs of looseness. Pay special attention to whether the waterproof connectors are intact and replace aging components if necessary. If any worn or damaged wires are found, repair or replace them in a timely manner to avoid potential safety hazards.

Optimize Electrical Connections: Provide an independent ground wire connection for each light and avoid the grounding method through screws. This can ensure more stable and reliable electrical connections and reduce the problem of poor contact.

Choose High-Quality Products: Select high-quality LED lights with an IP67 waterproof rating, such as the W226 lights. These lights not only have excellent waterproof and dustproof performance but can also maintain a stable working state in harsh weather conditions. Their robust and durable design enables them to work stably in various complex environments, providing higher safety and reliability.

It can be seen that side marker lights are very important for our safety. Firstly, don't be tempted by cheap and inferior lights. A good light can last for 5 years without breaking, which is a hundred times better than those cheap lights that break in less than a month. Moreover, high-quality lights, such as the AgriEyes W226 side marker lights, with their high-quality materials and good sealing, can effectively reduce the problems that may be encountered in daily work, saving you time and effort in maintaining these troublesome lights.